The concept of failure is a tool to break designers out of their established pattern during collaborative design meetings.

A building assignment is a complex task that demands collaborative working in order to achieve added value for users and society through creative construction management. Modular building systems are used in workshops in the building environment domain to make students aware of various phenomena that occur in the process of creative construction. Existing modular building systems used in training do not include the experience of failure as a motivator for creative construction.

An innovative Modular Building System (MBS) can be used as a tool in using failure as a motivator in creative construction.

The MBS consists of:

- 10 plywood disks, 600 mm in diameter, with 8 x 25 mm holes near the outer rim.

- 80 pine wood poles, 600 mm long, 22 mm in diameter, with 5 x 10 mm holes.

- 200 sticks, 600 mm long, 9 mm in diameter.

- 200 sticks, 100 mm long, 9 mm in diameter.

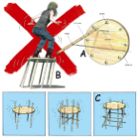

Upon inspection, it seems obvious that the poles have to go into the holes in the disk in order to build platforms of one or more stories high. The loose fitting of the poles in the holes, and the fact that the holes are placed in a large circle, causes the structure to fail as soon as it is loaded with some extra weight. Stability and strength are improved by placing some of the thinner sticks in some of the pole holes. Since these fittings are also rather loose, some thought has to be given to the direction and positioning of the sticks.

(A) Handstorm Modular Building System parts; (B) Failure of the simple construction of disk and poles and (C) Remedying this by thoughtfully positioning a few connecting sticks.

An MBS assignment was organized as a competition between the two groups at the end of a class on the management of innovation processes in design groups, which is part of the postgraduate Architectural Design Management Systems program at Eindhoven University of Technology. No specific guidance was given, and no examples of structures were shown.

The design students were allowed 60 minutes to design and construct a platform that had to be as high as possible, incorporate the smallest number of building parts as possible, and be able to carry the weight of all members of the group at the same time (one person on each disk). The groups worked in the same room and could observe each other.

One group first examined the building materials. No group leader came forward. The group started by making calculations to find out the best chance of winning with the supplied materials: greater height or fewer building parts. After 35 minutes, the group completed building and tested the construction. The structure failed. The reactions of the group members to the collapse ranged from laughing, looking helplessly at the spectators, examining the (broken) MBS parts, and asking the lecturer whether the collapse was a normal part of this methodology, and why these tools were not more robust. However, immediately after the collapse, the group started to construct a completely different platform. This happened without much discussion among the group members. It seems as though their hands automatically knew what they should do. In just three minutes, the concept of a new platform was born; three minutes later, the platform passed the loading test. The group spent the remaining 10 minutes optimizing the construction by reducing the number of building parts without losing stability or strength.

The designers of a group test their platform. It collapses, causing much hilarity among the group members, and leads to a new design

References

Gassel, F.J.M. van, Visser, M.J.E. & Bronswijk, J.E.M.H. van, (2013). Failure stress as a motivator for creative construction management. In M. Haidu & M. Skibniewski (Eds.), Proceedings of the Creative Construction Conference 2013 (CC2013), 6-7 July 2013, Budapest, Hungary (pp. 242-253).